Manufacturing in China Blog

Here you can leave comments and start discussions about manufacturing parts of complete products in China.

Comparative testing of Aluminium, Copper and Finned heat sink performance.

- Hits: 5432

- 0 Comments

- Subscribe to updates

- Bookmark

Advantages of using copper over aluminium for heat sinks are often discussed. If you look at high end CPU coolers for personal computers market for example, you will see extended use of copper. Coper thermal conductance is 4.01 W/cmK and aluminium is 2.37 W/cmK. With copper thermal conductivity so much higher that aluminium one would expect significant performance difference in real world. Let’s run some thermal tests.

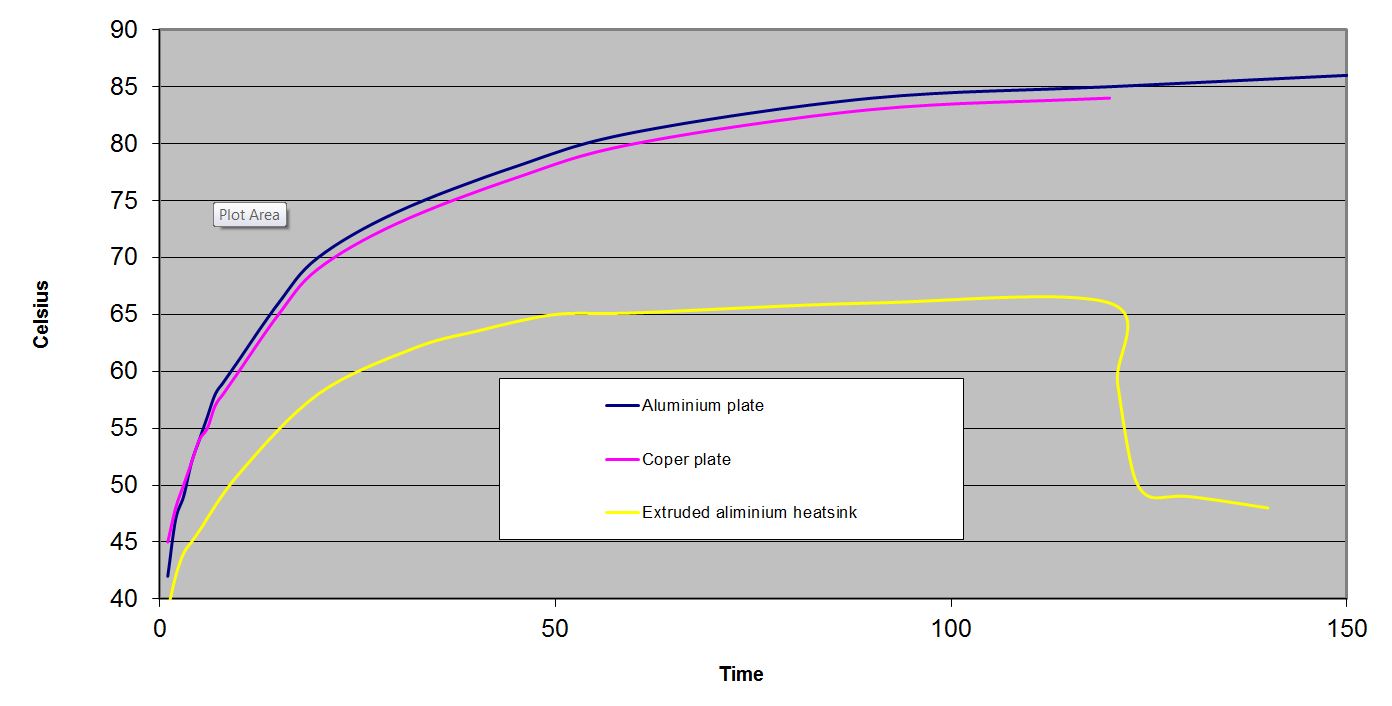

We have set up a test rig consisting of 200mm X 200mm X 2mm copper and aluminium plates. A heat source was chosen as power mosfet and was mounted in the middle of the plate. A continuos thermal load of 30 Watts was dissipated via heat sink. Temperature was measured at heat source (mosfet mounting pad). Ambient air temperature was measured at 24 Celsius and air was stationary.

During first 10 minutes there was no significant temperature difference between copper and aluminium heat sinks. We recorded 1 degree C and temperatures have reached 60C and 61C with cooper heatsink running cooler. Such a small difference can be accounted for the higher thermal inertia of the copper heat sink, as the mass is higher it takes longer to reach same temperature at fixed thermal input.

On 15th minute, mosfet mounted on to the copper heatsink reached 65C while mounted on aluminium heatsink was running at 66C. At about this point advantage of copper heat sinking becomes evident. By transmitting heat more efficiently, it allows components to operate cooler.

After 120 minutes, the 1 degree C thermal advantage remained valid. Temperatures reached 84C for coper and 85C for aluminium heatsink. There was no further improvement with coper versus aluminium, both plates have saturated at about 150 minutes maintaining same temperature difference.

Is the coper heatsink better than aluminium? Sure, thermal component will run cooler mounted on the coper. Is it wort additional cost as coper is so much more expensive and punishment of extra weigh? Maybe, depends on application. If you already exhausted all the possibilities of using cheap and light aluminium heatsink and chasing small improvement for the critical thermal system, then definitely coper is a great candidate.

Now, at the same time we had a third test rig with the extruded aluminium heat sink with finns and same mosfet dissipating 30 Watts of heat on it. It was cooled via conventional air flow. Heatsink was 1/6 the size of the plate, but had 50 mm fins on the back. It is old Pentium III cooler. Made out of extruded aluminium, about the same weight as our 200mm aluminium plate it performed great. After 120 min run, it reached only 66 degrees Celsius. Compare this to the 85C of the copper plate.

So by using same amount of material, copper or aluminium, you can have a dramatic improvement in heat dissipation just by altering the design of the heatsink. This is the most important message from the test result. Only when heat sink design has exhausted itself for particular application, then material choices worth considering. Or fan forced cooling, as been activated on 121 minute and resulted in finned aluminium heat sink temperature drop of 17C.

As tested by engineers at P&A International

Comments