Manufacturing in China Blog

Here you can leave comments and start discussions about manufacturing parts of complete products in China.

HeatSink Test – Extruded Aluminium versus Aluminium Plate

- Hits: 4014

- 0 Comments

- Subscribe to updates

- Bookmark

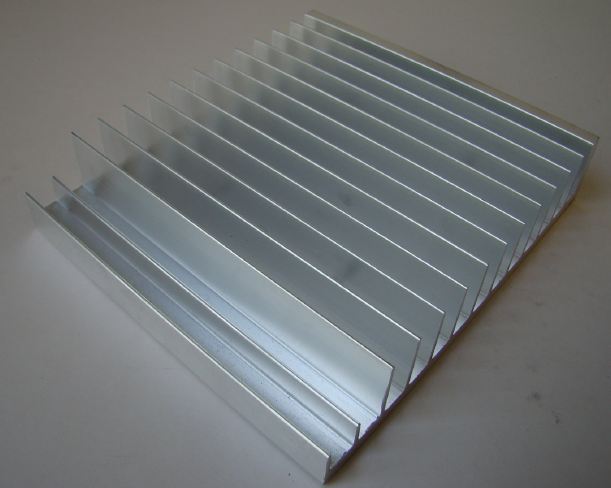

We all know that Extruded Aluminium heatsink will perform better than flat and low cost Stamped Metal heatsink, given the same size. But how much better is the diecast or extruded heatsink over just a flat aluminium plate? Lets do some testing, we will perform three separate tests. Finned heatsink, aluminium plate of the same size as heatsink and aluminium plate with the fan forced cooling.

We all know that Extruded Aluminium heatsink will perform better than flat and low cost Stamped Metal heatsink, given the same size. But how much better is the diecast or extruded heatsink over just a flat aluminium plate? Lets do some testing, we will perform three separate tests. Finned heatsink, aluminium plate of the same size as heatsink and aluminium plate with the fan forced cooling.

Test rig consist of 70 Watt thermal load applied by the centrally mounted resistor. The heat sink size is 100mm wide and 250mm long. Thickness of the fabricated aluminium plate is 4.0mm and extruded part is 5mm base and 15mm fins.

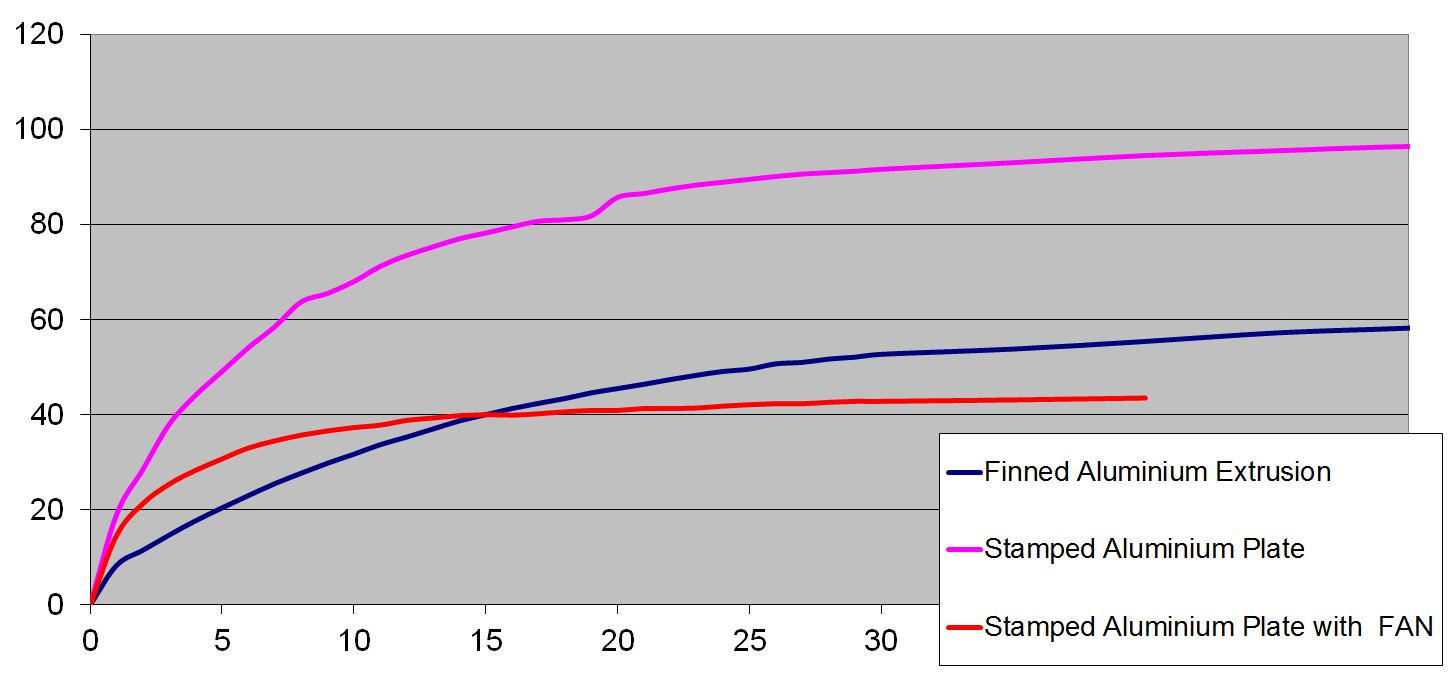

The chart represents temperature rise (above ambient) of the aluminium in degrees centigrade over the time measured in minutes. You can see that not just aluminium extrusion stabilised temperature been over thirty degree lower, but it also took five time longer to reach say 40C. This is caused by both, added mass of the heatsink (it’s twice as heavy) and improved heat dissipation via fins. Added base thickness of the extruded part also contributor to this factor allowing improved heat dissipation. The thermal inertia of the finned part can be a bonus to system with duty cycle less than 100%.

The interesting part of the chart is performance of the flat aluminium plate with the added forced cooling by the fan. While this is questionable method due to limited lifespan of the fan, the performance of the cooling device been really good. It quickly got up to saturation temperature of about 40c and stay there. That is a good example of efficiency of fan forced cooling and it’s place in the industry. Where possible, it will allow equipment designer to use much smaller and lighter heatsink with the addition off the cooling fan while achieving same of better result over the larger finned cooler.

Comments