Electrical Transformer Manufacturer in China

P&A offers a fast response with custom made electrical transformers quote and manufacturing with support to China and Asia Pacific countries. It just takes one phone call or email for our engineers to start looking in to your enquiry. Fully equipped with latest machinery, our China manufacturing facility is ISO certified ready to design and produce a sample of the custom electrical transformer to your specification. We can manufacture a sample of high frequency or high power transformer for testing in one week. You can have your electrical transformer or inductor made and shipped directly from China to your doorstep in two weeks.

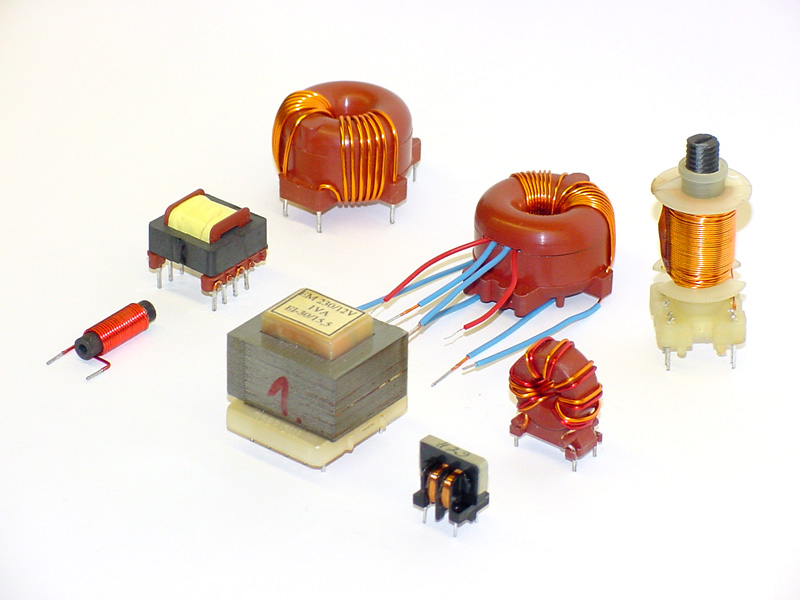

Transformers manufacturing in China:

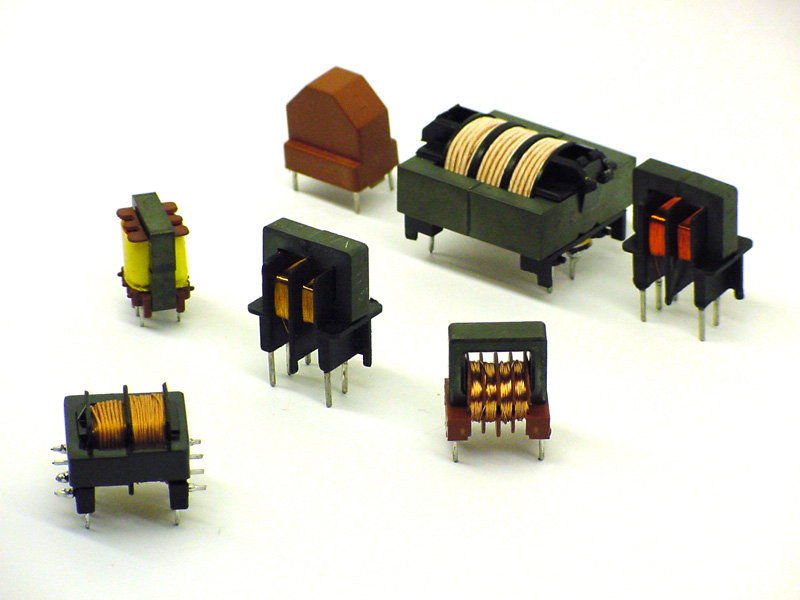

Every household electrical appliance designed today utilise an electrical transformer or magnetic inductor of some sort. Over the years we have observed the shift from EI type of transformers to Toroidal. Later on a new trend has emerged and all major manufacturing companies started to source transformers from China. Due to inductors simplicity in design and manufacturing, China been able to quickly adapt and supply a high quality transformers. In year 2000 a new trend have gained momentum in power supply industry, called Switch Mode Power Supply. Government electrical efficiency regulations and new complex consumer electronics where demanding a new type of power supply, that is more advanced, efficient and smaller. Consisting of many electronic components, switchmode power supplies use high frequency transformers that are much smaller but more complex to manufacture and a challenge to China manufacturers. Some of the best factories in China have purchased Japanese equipment and training in order to satisfy newly created demand. We now enjoy the benefits of cheaper Chinese labour and high quality high-frequency transformers used throughout switchmode power supply industry as well as solar power inverters.

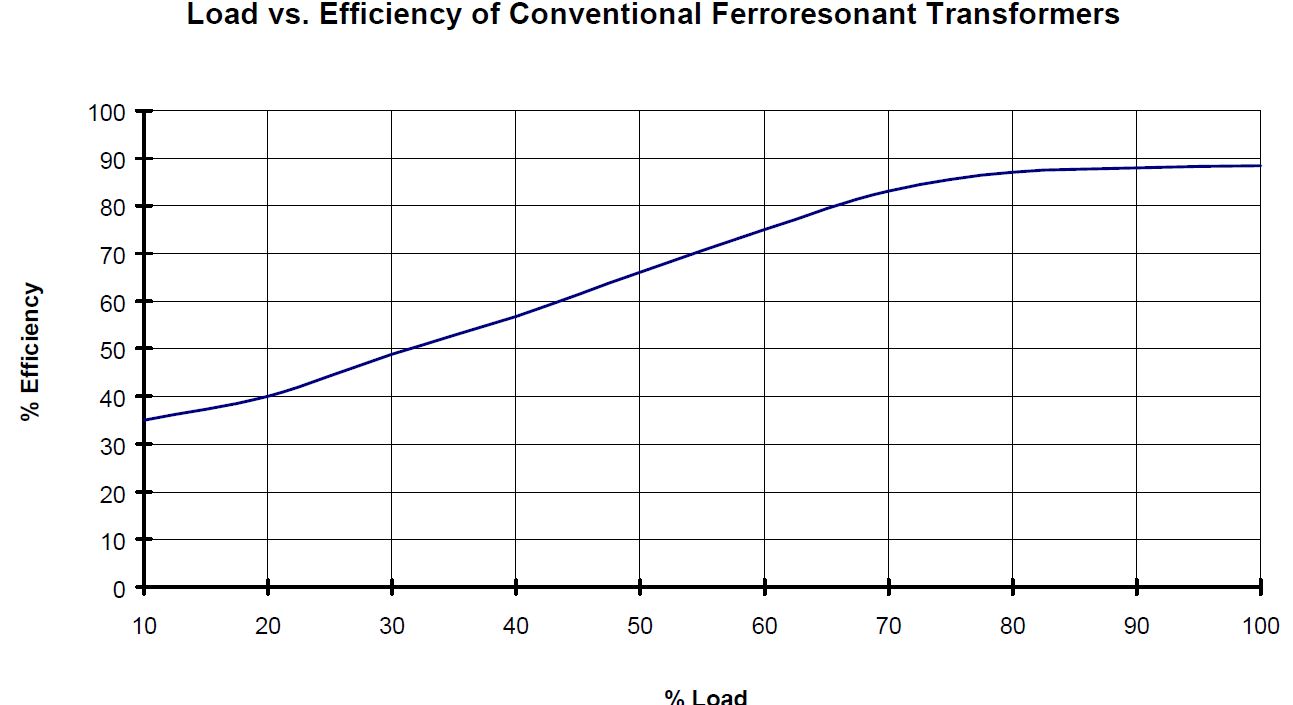

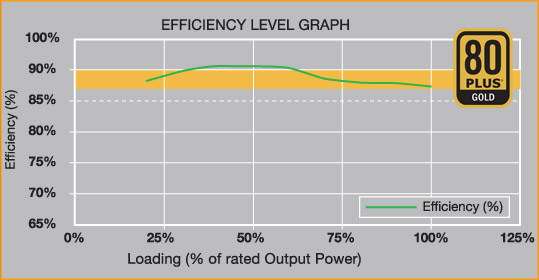

Charts below represent Switch Mode Power Supply (on the left) and Electrical Transformer (on the right) efficiency comparison. Keep in mind that SMPS efficiency chart include losses in AC to DC rectification and control curcuitry. While Transformer efficiency chart show transformer performance only.

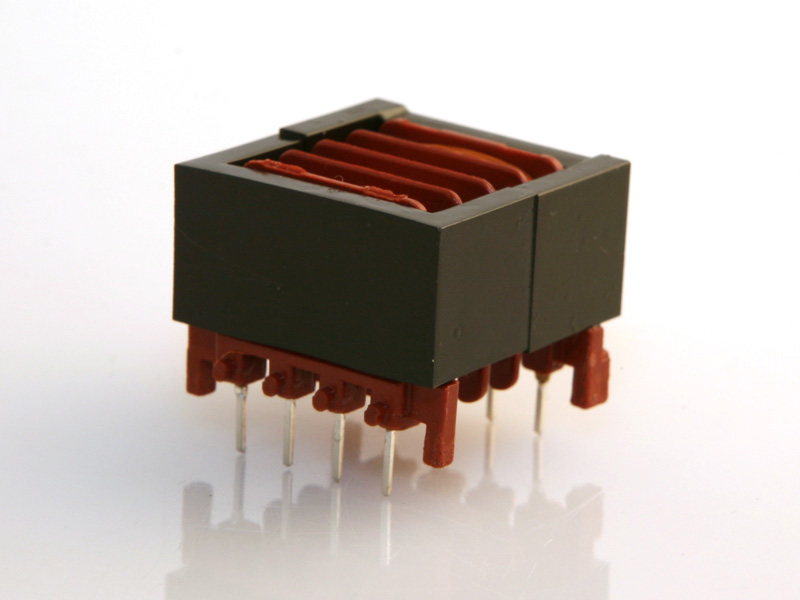

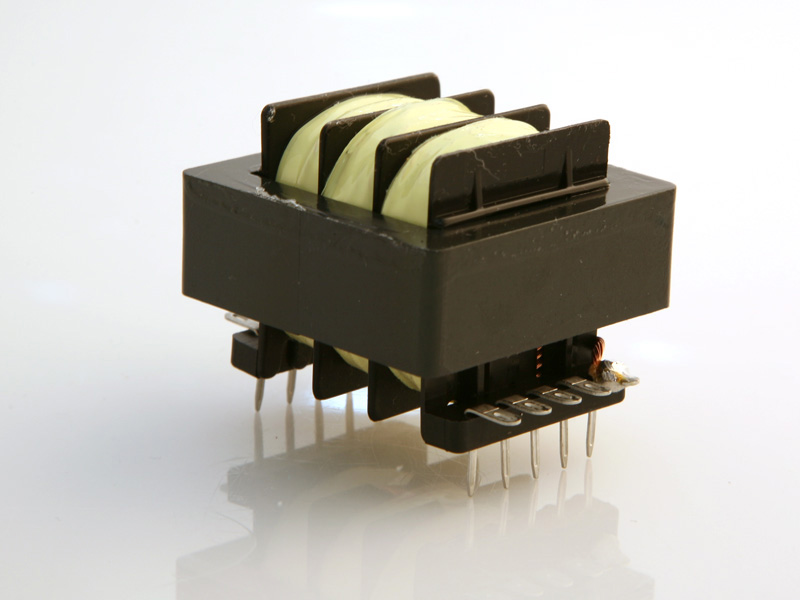

EE and EI Transformers:

- A wide range of single or multiple voltages, currents or power

- Low idle losses

- Excellent heat dissipation

ER, ETD and PQ Transformers:

- Provide an optimized ratio of volume to winding area and surface area

- Good heat dissipation.

- High power output

- Low idle losses

EFD, EP and EPC type of Transformers offer:

- Wide range of power rating.

- Excellent magnetic shielding

- Good heat dissipation.

- Low idle losses

POT and RM types of Transformers:

- Good magnetic shielding

- Small distributed capacitance

- Can be supplied gapped with tuner

- Well-suited for high Q inductors & tuned transformers.

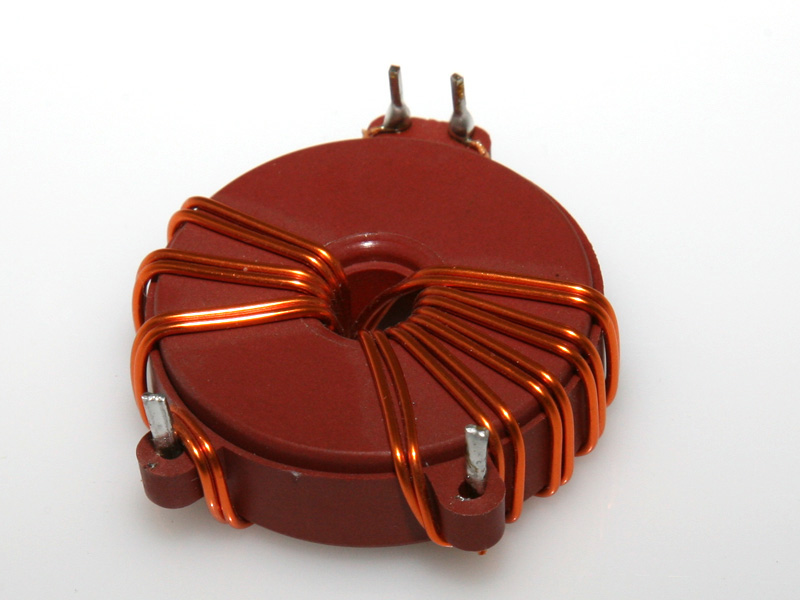

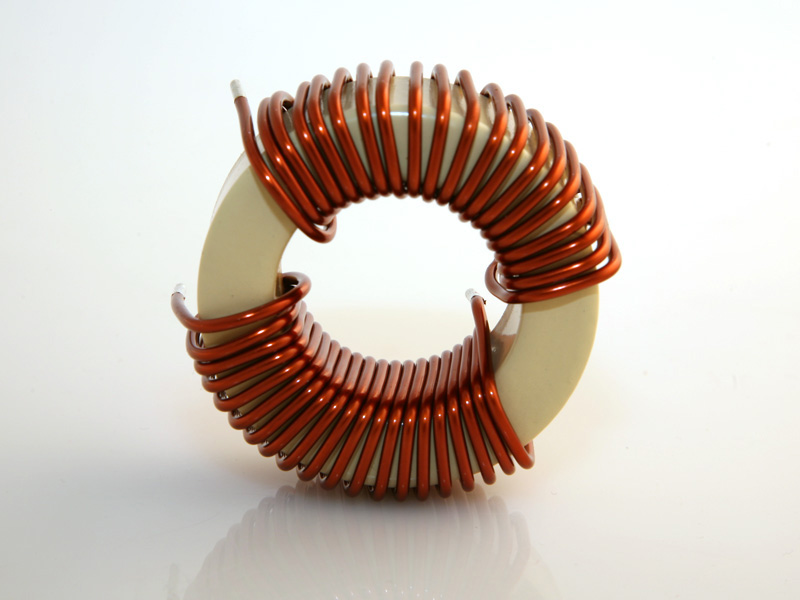

Toroid / Toroidal Transformers:

- Can be made of any size

- Wide range of power output

- Low exterior magnetic field

-Wide range of input/output voltages available

- Low idle losses

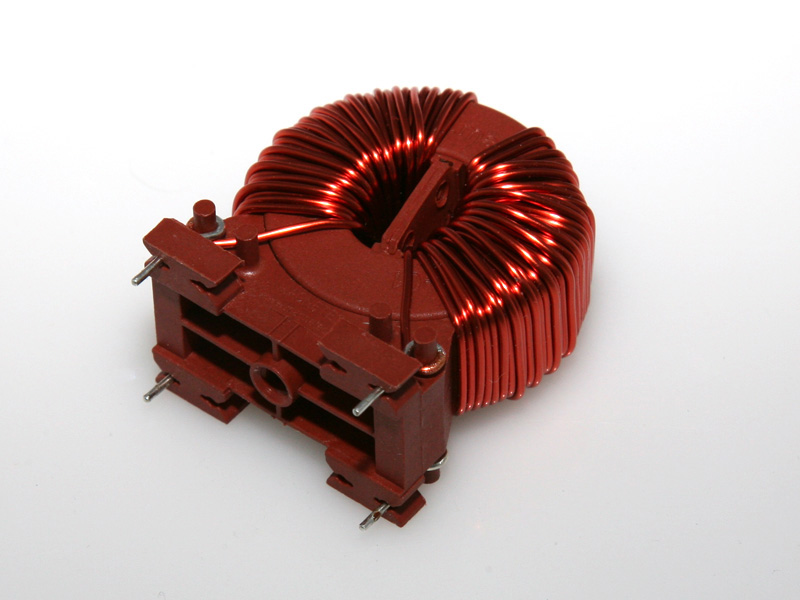

Wire type Transformer:

- Wide range of power output

- Good heat dissipation

- Low idle losses

High Standards Guaranteed

P&A International enjoy longstanding relationship with testing authorities in both Australia and China. This ensures that all products supplied by manufacturers comply with current electrical safety standards (AS/NZS) for a variety of applications. On behalf of its customers, PA International has also worked with various testing authorities to assist customers in obtaining electrical approvals of their products.

Points to consider when ordering Transformers

Approvals

Custom transformers can be designed to the applicable sections of other standards, such as: UL, IEC, VDE, CSA, AS/NZS and others.

Insulation

Unless specified otherwise, transformers are made to meet Class B (130°C). However, we use four UL approved insulation classes, which may be specified as required, up to class H (180C).

Temperature Rise

Transformer temperature rise may be specified as required in given operating ambient. The basic design guideline is 60°C. With a Class B (130°C) insulation system, this would allow operation in a maximum 70°C ambient.

Inputs

Most common input voltage for transformers is 220VAC. We can design and manufacture transformers with other voltage inputs including multy-voltage tapings.

Line Frequency

Standard transformers are designed to operate at 50 or 60 Hz. Grain oriented steel cores can be used at frequencies up to 2 kHz. For higher frequencies we use such materials as ferrite, powdered metal and other composites.

Power

Power requirements up to 25 kVA per phase (75 kVA for three phase transformers).

Outputs

The output loading of the transformer may be specified in either of two ways:

-AC (RMS) voltage and current (IAC) or power (VA) and duty cycle for each secondary output.

-DC load parameters. We can engineer the optimum transformer from your specific DC load data. This data should include: DC voltage, current, rectifier type (full wave, full wave bridge, etc.) and specification, capacitor type and value, regulator type and specifications, and special load characteristics, including duty cycle. Please supply a simple schematic, if possible. With this information, we will determine the optimum secondary AC specifications for each output.

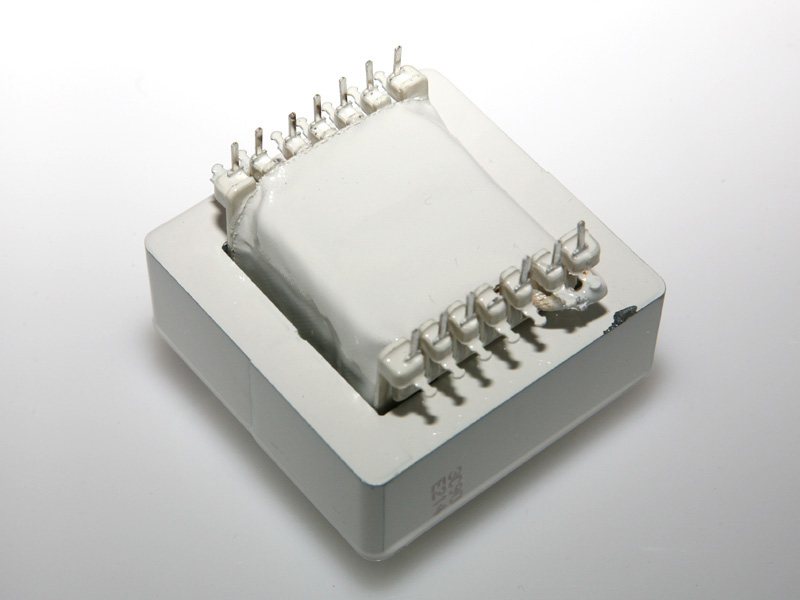

Mounting

In addition to the standard potted center toroidal transformer and mounting disk with washers, we can supply custom toroids with threaded inserts, bushings, or studs pressed into a potted center; special molded bases; complete molded enclosures; printed circuit mount cases or custom sheet metal brackets and enclosures.

Leads

Leads may be specified as solid (stripped and/or tinned) or stranded (with special stranding ratios, stripped and/or terminated). Insulation layers and type may be specified (Teflon, PVC, single, double, etc.). Lengths of transformer leads are required.

Thermal Protection

Customer specified temperature and type: self resetting switch or fuse. We use specially packaged (for high mechanical stress) internationally approved devices in our transformers.

Electrostatic Screen

Customer specified. To reduce capacitive coupling, and/or create a physical barrier insert (known as safety screen), between primary and secondary or between specified secondary’s windings of transformer. Copper foil laminated between insulation provides 100% coverage.

Magnetic Shield

Toroidal transformers radiate about 1/10 the magnetic field of standard EI transformers, but to further attenuate stray magnetic fields in very sensitive applications, such as in close proximity to a CRT, an additional magnetic shield may be called for. Magnetic shields consist of multiple layers of grain oriented silicon steel, or a high nickel content alloy, such as MU-Metal, Magnifier 79, etc.., laminated between insulation. Wrapped around circumference of transformer. Disks are also available for use within potted assemblies.

Mechanical

Height and diameter of the electrical transformers made to suit, as long as the core cross section is held constant.

Additional Documentation

Predicting Temperature rise of Electrical Transformers part 1

Predicting Temperature rise of Electrical Transformers part 2